Chances are you’ve landed on this article because you’re interested in putting together your own rosin press instead of buying from a brand name manufacturer. No problem, we’ve got you covered. In this article we’ll go over everything you need to know to build your own rosin press as we discuss everything from the necessary equipment you need, breaking down the associated costs, looking at potential yields, and recommending complete builds to accommodate different budgets and price points. Let’s begin, shall we?

DIY Rosin Press – How to Make a low budget Rosin Press (under €500,-)

That being said, not all shop presses and plates are created equal. You probably have a budget in mind on how much you’d like to spend putting together a rosin press; working with a higher budget means being able to buy higher quality equipment, which means longevity and possibly getting more use out of your press over the coming years. Fortunately, our years of experience and expertise in this industry having interacted with over hundreds of customer, speaking with people just like you puts us in a good position to recommend only the best equipment that “just works” while keeping a budget in mind.

What kind of equipment is needed?

When it boils down to it, putting together your own rosin press is pretty simple since all you need are two things:

- A Shop press

- Rosin Plates and Heating Controller

Shop Press

The engine of your soon-to-be rosin press starts with a humble shop press. Keep in mind that these shop presses were meant to press bearings in the garage or shop once or twice a month, or maybe used just a couple of times a year. The common feedback we’ve heard among our customers is that while these shop presses are generally inexpensive, the quality of the steel on these aren’t too good. There are of course higher quality shop presses available for higher prices (more on that later on).

When purchasing a shop press, most of them differ by capacity. The most common ones are 6-tons (12,000lbs), 10-tons (20,000lbs), 12-tons (24,000lbs), and 20-tons (40,000lbs). So, you’d want to ask yourself how much you intend to press and how much material you are working with on a consistent basis. Buying a higher capacity press means you’re able to exert more force and squish more material. However, the amount of material you can squish is relative to the size of your rosin plates. The larger the plates, the more material they can accommodate, the more costly they become—keep this in mind if you’re trying to stay under a certain budget.

Most of the presses can be had for under €300, and some even under €100. Here is our pick of the recommended shop press used for DIY rosin presses.

10 ton Shop Press

Hydraulic workshop press from the George Tools brand. This table model has a capacity of 10 tons. The press table is adjustable in different heights. The width of the press table is 34 cm and the depth is 13.5 cm. This table press is very suitable for bending or straightening. A press is also used to remove or place screws and bolts, for example.

Rosin Plates and Heating Controller

While there’s a plethora of companies manufacturing rosin plates and heating controllers, we’ve narrowed our choices down to the following plates & heating controller sets since feedback on them has been great while hitting our budget mark. As always, we’re on the lookout for what’s new and great, so you can rest assured we’ll update this article and inform you of any new DIY kits that we scope out.

There are not many good and reliable kits for the European market yet. We still found one that we can recommend without further ado.

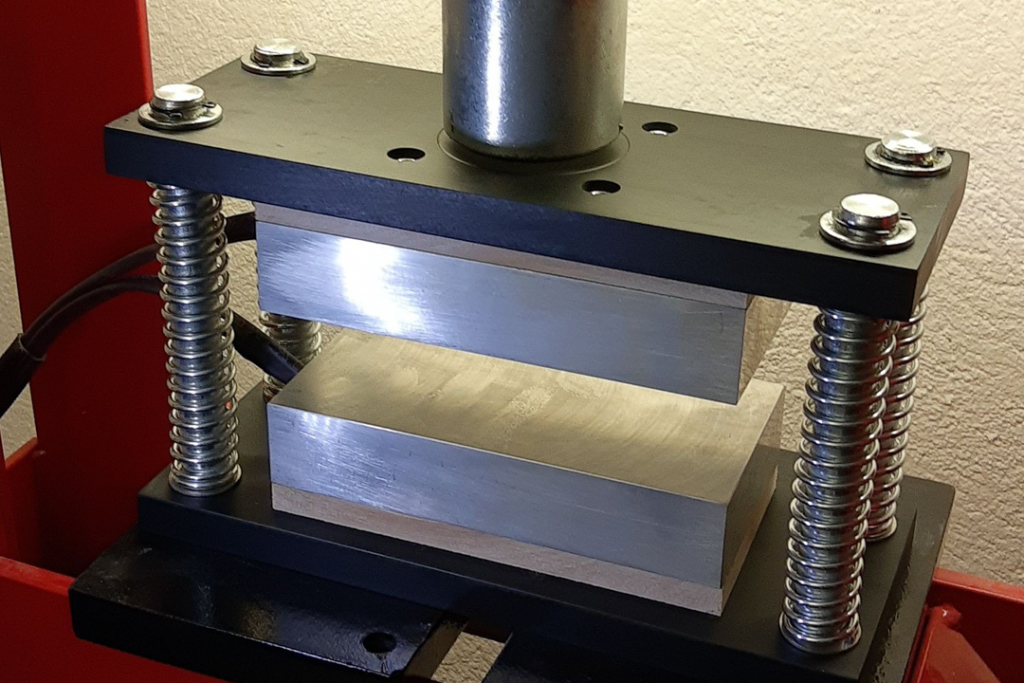

Graveda Cage Plates

With the 15 x 7.5 cm plates you have more than enough space to let off steam with your extracts. The control unit supplied reaches a temperature of up to 150 ° C so that a perfect temperature can be found for every man or woman. Because the plates are already mounted on the cage, you only have to choose a suitable frame for you. Now just attach the CagePlates, plug in the control unit, connect the power cable and off you go with the extraction!

Build it up dude!

Now we have all the necessary components to complete our press. If you have decided on our two components, proceed as follows. Turn the cages plates upside down and place them exactly under the stamp of your new tool press. Connect the power cable and check the power and temperature control on the controller. Everything works? – Then you are ready, press your own concentrate. Every day.

Our conclusion

As you see, putting together a rosin press can be had for very little money. For less than €350, you can start producing your own concentrates at the comfort of your own home and watch that oil drip! Now that you’ve built your rosin press, you can start pressing your material and start making luscious rosin, right?! Err… not quite, but we’re almost there. There’s just a few housekeeping things we’d like to go over before you go out and build your press so continue reading on…